Contact Us

Tel:0086-574-66219838

Fax:0086-574-62637985

Post Code: 315400

Contact: Weng Keqing

Telephone:13429261888

E-mail:feida@fideksealing.com

Home / News / Industry News / Basic knowledge of expansion joints of silicone cloth and fluoroplastic cloth

Basic knowledge of expansion joints of silicone cloth and fluoroplastic cloth

Date:20-05-06

Expansion joint, also known as compensator, expansion joint. It is an indispensable important link of modern pipeline engineering system.Fiberglass silicone rubber cloth

The pipeline system will cause thermal expansion or cold expansion and contraction of the pipeline due to temperature changes in the two states of shutdown and startup. If these expansions or expansions cannot be compensated (eliminated), it will cause serious damage to the system and prevent the system from working properly. Expansion joints are used to absorb these thermal expansion or cold expansion.

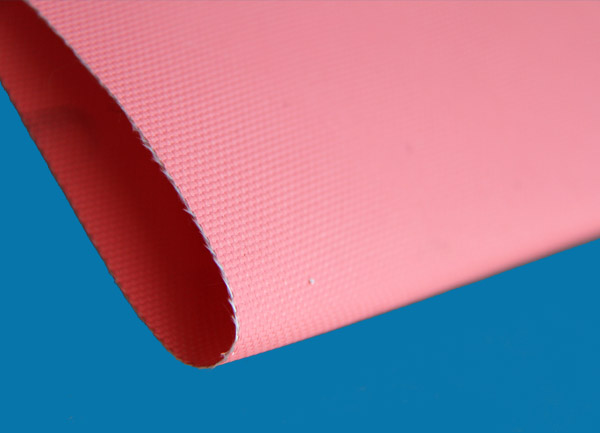

The middle section of the non-metallic expansion joint is connected by a soft non-metallic skin, filled with thermal insulation cotton inside. The skin is made of fiber fabric coated with silicone rubber or fluororubber, which has excellent stretching and lateral misalignment functions. Insulation cotton isolates the high temperature of the medium in the pipeline from the skin, forming a temperature gradient from inside to outside, reducing the pressure on the skin. Due to the rapid progress of modern science and technology, the comprehensive performance of the deputy secretary materials such as high temperature resistance, acid and alkali resistance and chemical stability has far exceeded that of metal materials. Non-metallic expansion joints have replaced metal expansion joints in many fields.

Scope of application of non-metallic expansion joints:

1 The flue system of a power plant

2 Low-pressure airflow piping system of chemical plant

3 Piping system of cement plant

4 Flue system of thermal power plant

Maintenance and replacement performance: Non-metallic expansion joints do not require maintenance during the normal service life cycle. It is much more convenient to replace non-metallic expansion joints than metal expansion joints. This is especially noticeable for large-sized expansion joints.

Service life: The service life of the expansion joint is closely related to the environmental conditions. In coal-fired power plants, in general, the service life is more than 5 years. It is not uncommon to use it for 8-9 years under working temperature below 300 ℃. The situation of the oil-fired power plant is more complicated. If you burn light oil, diesel oil, the service life of the expansion joint can generally be 3-4 years. If you burn heavy oil or crude oil, because of the frequent cleaning, the damage to the expansion joint is relatively serious, generally only 1-2 year.

Operating pressure: Non-metallic expansion joints can be divided into composite expansion joints and rubber expansion joints. The working pressure of the compound expansion joint is generally not more than 0.5 atm (50Kpa), and the pressure of the rubber expansion joint can be more than ten atmospheres or even higher.